e3D MIM CAD Build Solutions

AECOsim is a powerful BIM CAD system that caters to all disciplines in one modeling environment. The system itself is very complex, with six different data systems that build upon each other to create the necessary project data. However, modeling, creating drawings, and generating the project data from the 3D models are easy to do (once the correct data has been added). From experience, users will not use complicated systems and custom nested menu's which is why we have consciously made the front end of the system as simple as possible, even more so with the CADnet user interface to find the 1,000’s of model library components (see the 3D and 2D CADnet features).

e3D's approach to creating workspaces is never to customize the application but instead populate the data within the delivered "out of the box" workspaces with the correct data for the intended subject matter. The software needs to work the way the software developers intended it to work.

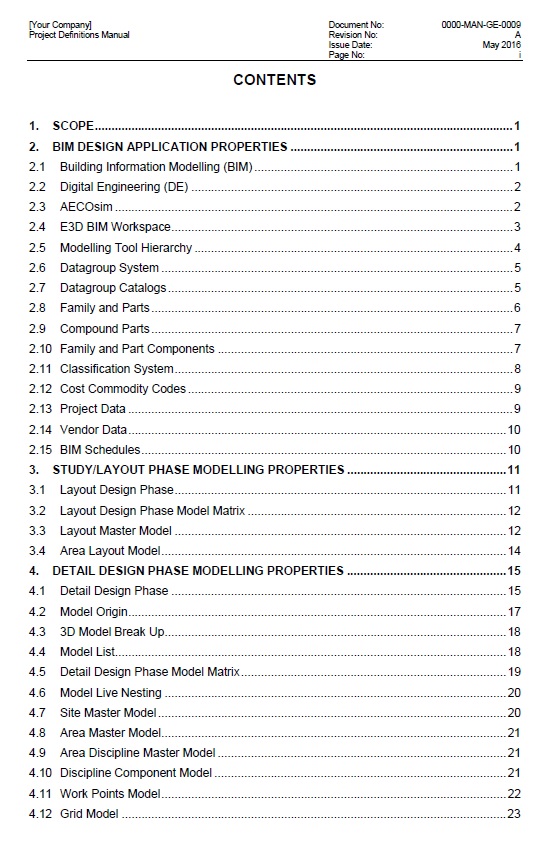

Reverse engineering the data from previous mega-projects means that almost every component used in mining has been added to the CAD Build. Having the correct data makes using the application very easy; everything you need is in the CAD Build. Using the holistic top-down and bottom-up approach with the end product in mind strikes the right balance of efficiently modeling detail, creating drawings, and generating MIM data required to deliver high-quality projects for mining.

If your Designers and Engineers already know how to use Microstation, Bentley Structural, or your current AECOsim CAD system, there is no change from how they are currently working. If your Designers and Engineers are presently using a CAD system other than Bentley's CAD system, then allow one week of watching e3D's training video's (or one on one sessions with our CAD support team) to be competent with using AECOsim.

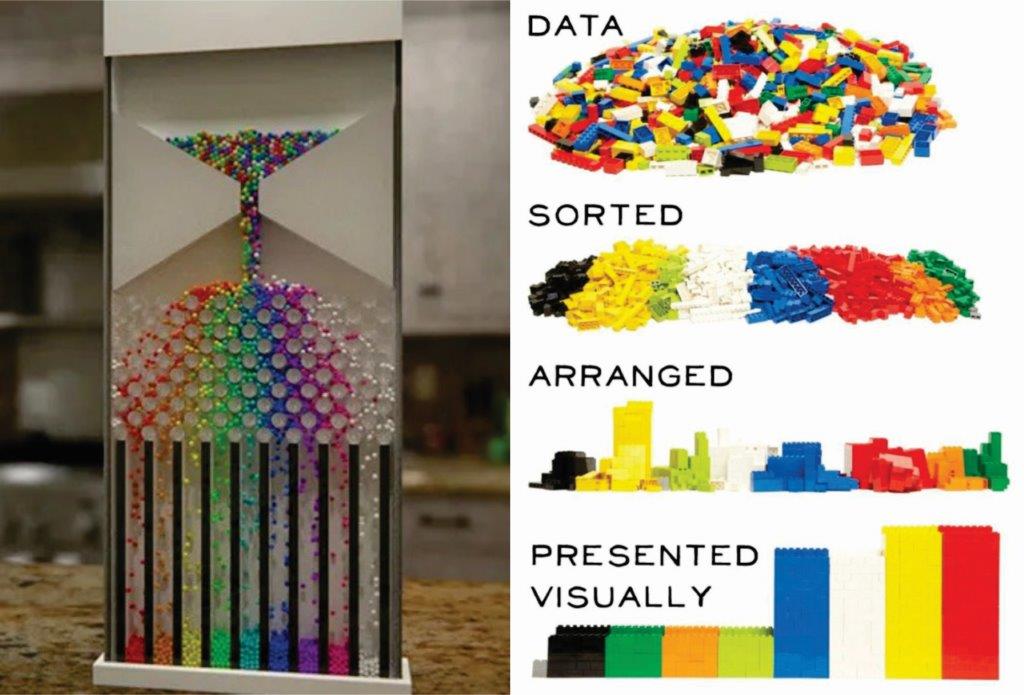

Mining projects vary from small brownfields to large mega-projects; the scope can vary from Wet Plans, Dry Plants, Process Plants, Airports, Camp and Mine Facilities, Bridges, Tailings Dams, Rail, Marine Ports, etc. The MIM system captures relevant data about every component modeled instantly, so depending on the project, the amount of data captured can be enormous. The amount of data can be so extensive that it is no longer helpful unless it can relate to a specific facility and subject matter within that facility.

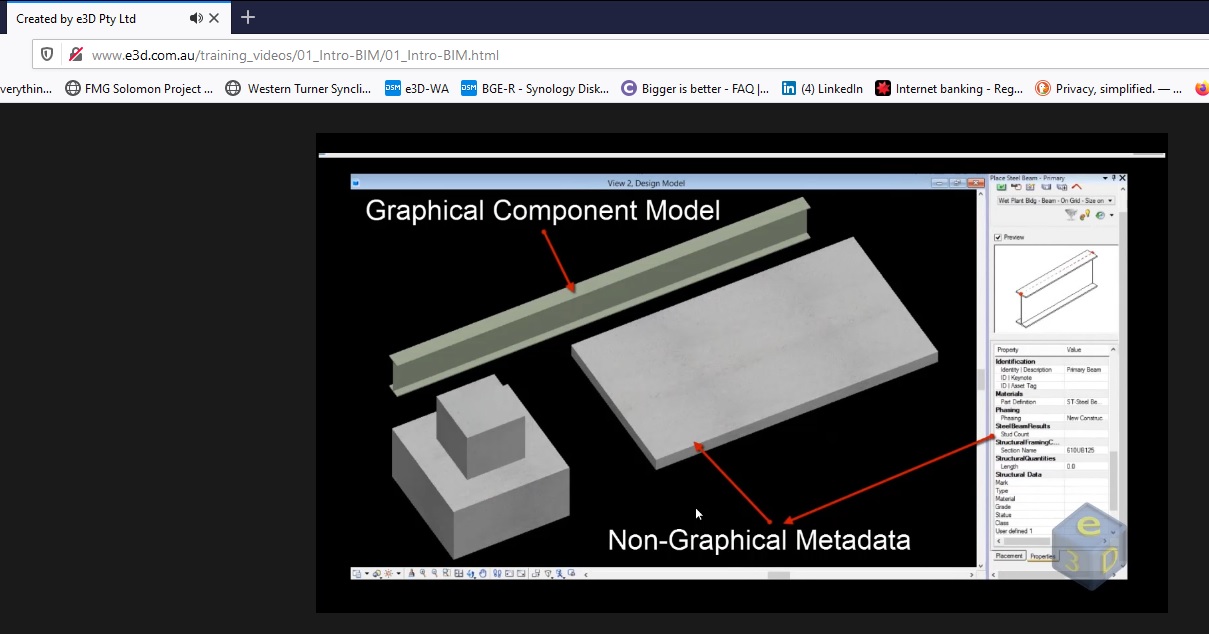

It is the structured data that is the foundation of e3D's MIM CAD Build. The additional data fields supplied with e3D's CAD Build tell you how each component relates within the projects and can be sorted and filtered to provide information for all other project activities, such as

- Task line items in Construction Schedules makes for very accurate schedules and reduces the effort required to create the schedule by enabling the Scheduler to focus on logic, durations, and resources rather than data entry.

- Line items in Cost Estimates makes for very accurate Cost Estimates and reduces effort by enabling the Cost Estimator to focus on the costs rather than data entry.

- Line items for Procurement and associates the Procurement details to the actual detail design components.

- Automates the linking of schedule tasks to the 3D models, drastically reducing the effort required to create 4D, 5D, and 6D Construction Schedule Simulations.

- All non-graphical metadata stays with the 3D models and is carried thru into the construction phase.

- All non-graphical metadata stays with the 3D models and is carried thru into the Operations and Maintenance phases and finally used in the asset's demolition.

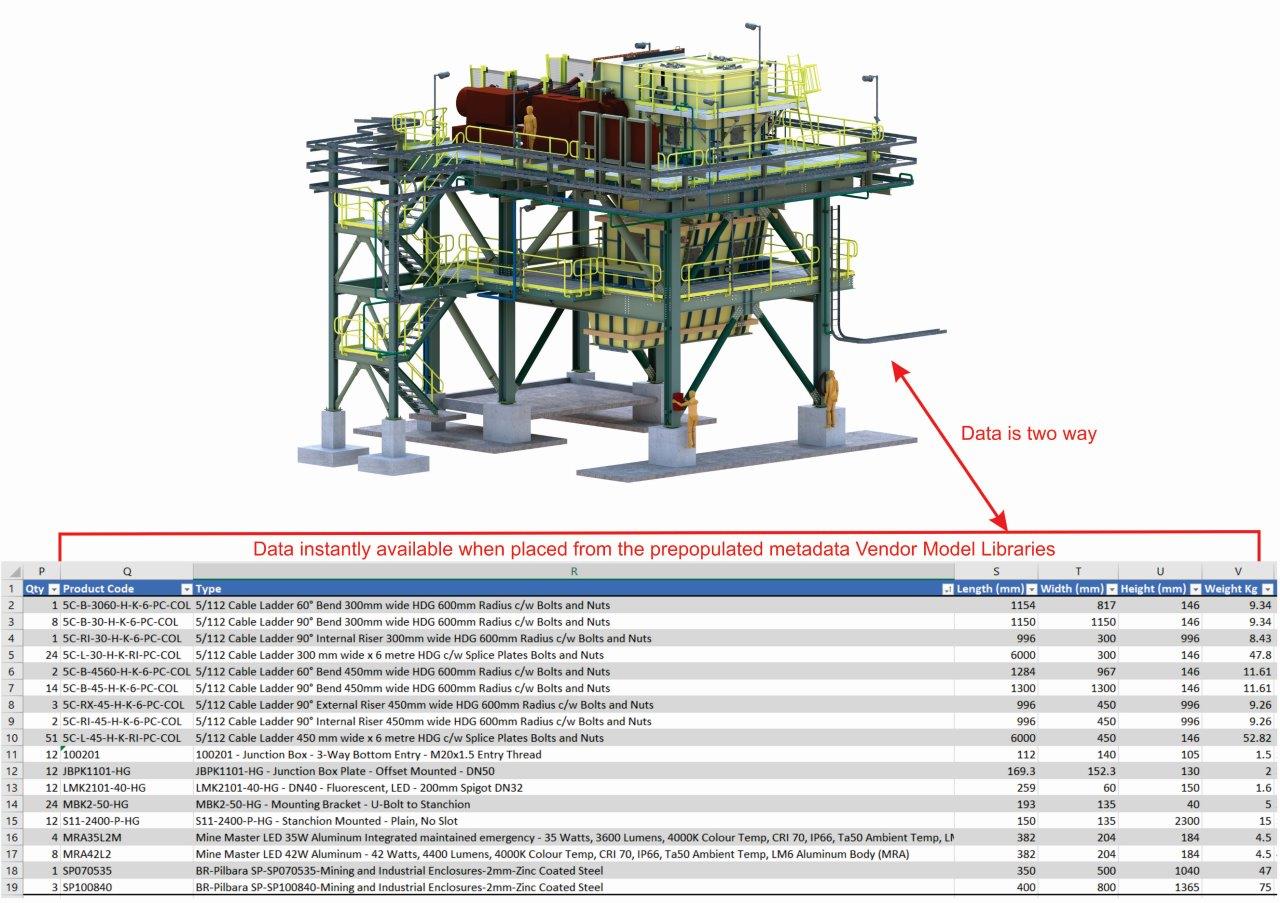

And the data is two way, update the data in the spreadsheet and it will update the model and vica versa.

All the available data is difficult to show here, so a small snapshot of the data will have to suffice; ask us for a demo so we can show you everything. An example of the Electrical Vendor consolidated MIM data generated directly from the design model,

Imagine the manhours saved with your Designers and Engineers being able to pick and place these items directly from the prepopulated metadata Vendor model libraries.

What could your Schedulers, Cost Estimators, Procurement do with this highly accurate and actional data directly from the single source of truth design models? You can see how this reduces project risk and speeds up the project engineering phase.

30 x Vendor libraries have been created consisting of 12,198 components which are supplied with the system.

The prepopulated metadata 3D model Vendor libraries provide huge efficiencies in the detailed design of Mining plants; imagine your designers just picking and placing vendor models into the design rather than spending many hours modeling these components. Someone in the project has to model these components, show them on a detailed design drawing, cost estimate them, schedule them, procure them, transport them to the site and install them. The e3D MIM CAD Build enables the Designer to place the components from the prepopulated metadata Vendor model libraries in seconds to provide the information from the single source of truth for all of these activities, saving days, weeks, months of hours to create lists of these components manually.

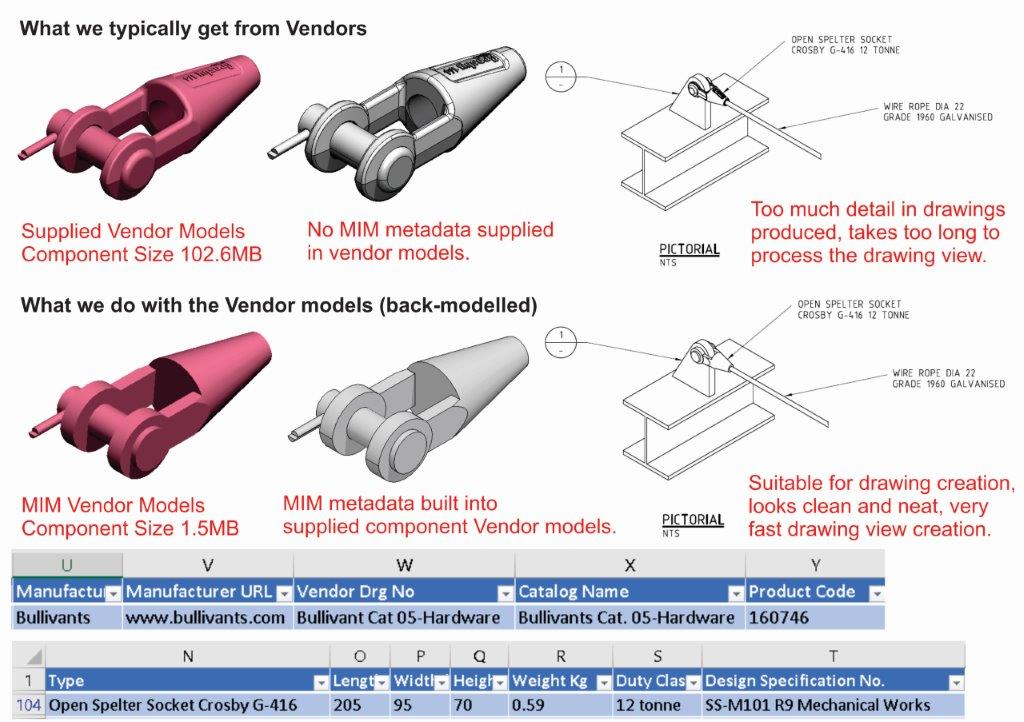

By having the Vendor models back modeled from within AECOsim, allows the right balance of detail for the subject matter, dramatically speeds up the design process and drawing production. Quite often, the Vendor supplied models (if we get any) have too much unnecessary detail, like engraved logos, fillets, chamfers, etc. The supplied vendor models created by using different CAD systems cause problems. Using Vendor supplied models, we found that Gigabytes of extra detail and huge file sizes slowed the loading of the 3D models and hampered drawing production. The resulting drawings reflected the unnecessary detail from the Vendor models. We found by having clean AECOsim generated simplified Vendor model libraries with the important interfaces and Vendor metadata added to them that this was the best way to do the detailed design of projects efficiently.

We see the Vendor model libraries' development as a never-ending task and are constantly adding more libraries to the system.

Electrical

- Swivelpole Australia - Junction Box Plates, Luminaire Mounts, Mounting Brackets, Poles C, F, H, R, S & ST (119 components).

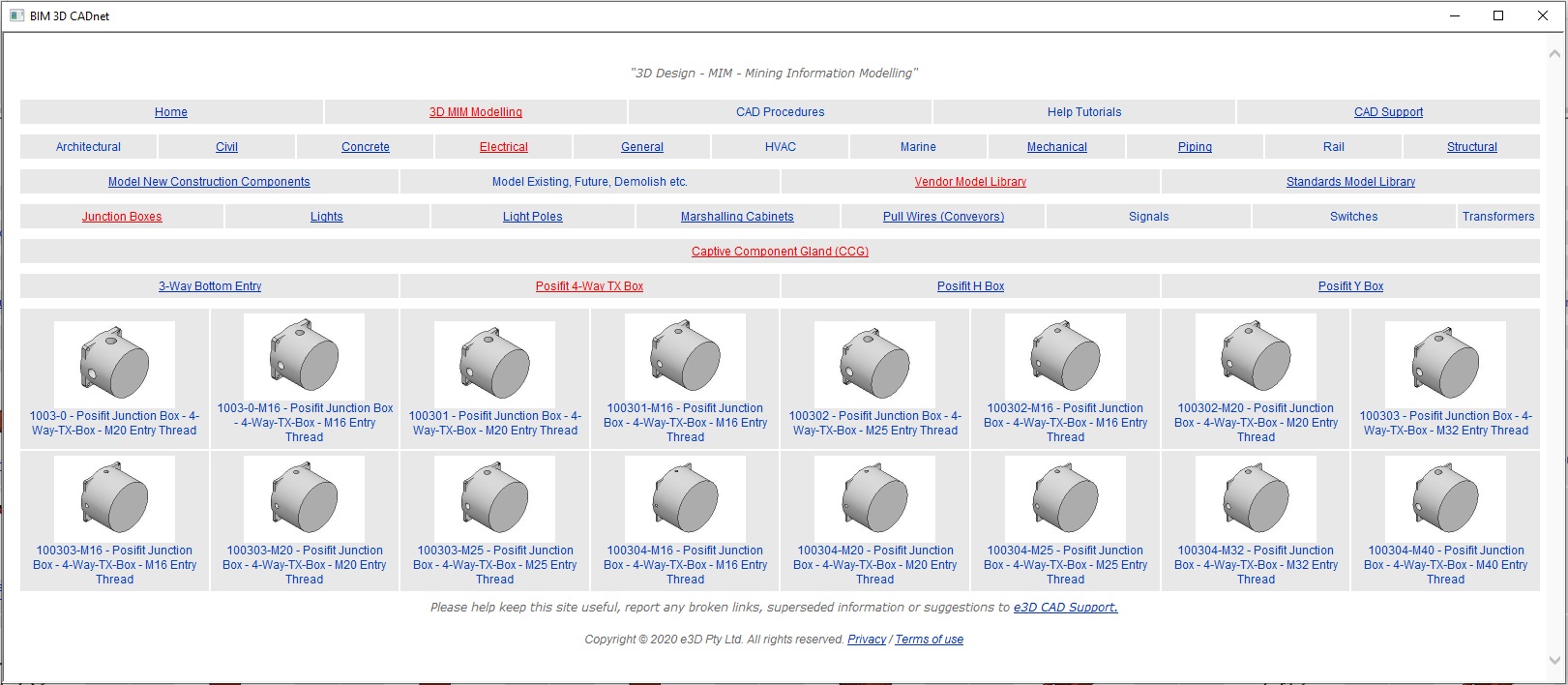

- Captive Component Gland (CCG) - Junction Boxes - 3-Way Bottom Entry, Posifit 4-Way TX Box, Posifit H Box & Posifit Y Box (34 components).

- Dialight - Lights - Durosite, Safesite & Vigilant (108 components).

- Pierlite - Lights - Mine Master HID, Mine Master LED Gen 2 & Vandalux (20 components).

- B & R Enclosures - Bowen Series, Connector TEMF, Custom Enclosures, Finucane, Hedland, Incline, Lambert, Miner, Monarch, Pilbara & Universal (202 components).

- NHP Panelboards - Concept One, Concept Plus, Concept Premier & Concept Tough (343 components).

- Austdac - Conveyor Pullwire - Pullkeys, Lanyards, Mounting Plates, Cable Clamps, Shackles, Turnbuckles, Springs, Thimbles, Rigging Screws, Safety Tags, Pigtails (35 components).

Mechanical

- Coventry Bolts - Hex HD Galvanized, Hex HD SS, Hex HD Screws Black, Hex HD Screws Zinc Plated, HT Hex HD Black, HT HEX HD Black, Socket HD Cap Screws Black & Socket HD Cap Screws Zinc Plated (1,848 components).

- Blackwoods - Split Pins - (176 components).

- Crosby - Chain Connecting Links - (16 components).

- Crosby - Chain Master Links - (20 components).

- Crosby - Eyebolts - Metric Course & Metric Fine (21 components).

- Crosby - Eyenuts - Imperial BSW, Imperial UNC, Imperial UNF & Metric Course (32 components).

- Crosby - Rigging Screws - Clevis to Clevis, Clevis to Eye & Eye to Eye (33 components).

- Crosby - Shackles - Screw Pin Anchor, Screw Pin Chain, Round Pin Anchor, Round Pin Chain, Bolt Type Anchor, Bolt Type & Bolt Type Chain (116 components).

- Crosby - Sockets - Open Spelter, Closed Spelter, Open Swage, Closed Swage & Mooring (103 components).

- Crosby - Thimbles - Open Pattern, Standard Wire Rope, Extra Heavy Wire Rope & Solid Wire Rope (53 components).

- Crosby - Turnbuckles - Clevis to Clevis, Clevis to Eye, Eye to Eye & Stub to Stub (50 components).

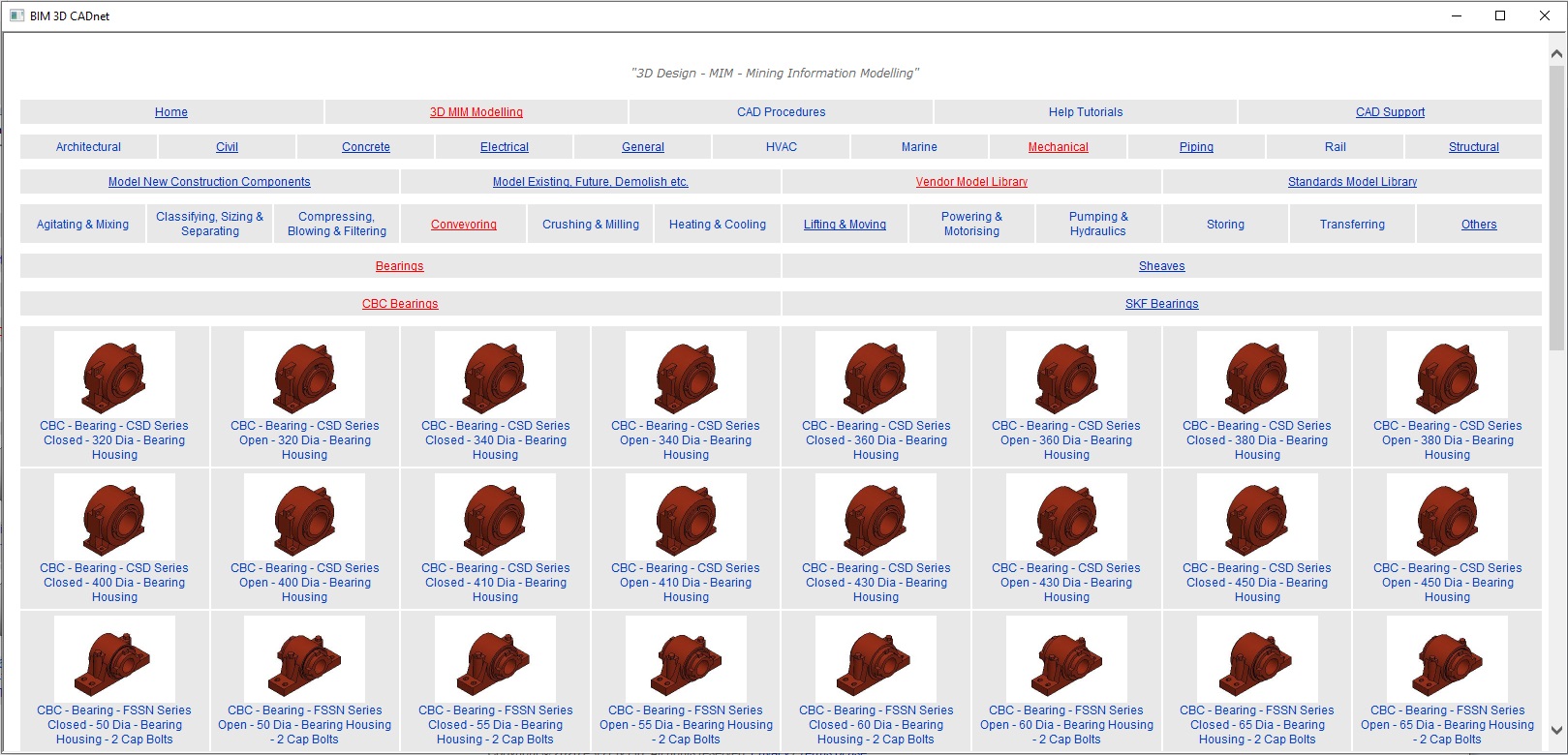

- CBC Bearings - MIM Data Includes - Adapter Sleeves, Bearing Housing, Sealed Roller Bearing, Spacer Rings & Housing Seal Assmembly (72 components).

- SKF Bearings - MIM Data Includes - Adapter Sleeves, Bearing Housing, Sealed Roller Bearing, Spacer Rings & Housing Seal Assmembly (66 components).

- Eilbeck Cranes - Sheaves - (10 components).

- Nobles - Sheaves - (26 components).

- SuperCrane - Sheaves - (4 components).

- Mackay Industrial Rubber Technology - Multicushion, Buffers, Isolators, Bushes, Safety Products, Power Transmission, Universal Hoses & Miscellaneous (500 components).

- Komatsu Mining Corporation - Idlers - To suit 2200mm Wide Belts (17 components).

- Komatsu Mining Corporation - Pullies - To suit 2200mm Wide Belts (26 components).

Piping

- Binder Group - Pipe Supports (5,000 components).

Structural

- Coventry Bolts - Hex HD Galvanized, Hex HD SS, Hex HD Screws Black, Hex HD Screws Zinc Plated, HT Hex HD Black, HT HEX HD Black, Socket HD Cap Screws Black & Socket HD Cap Screws Zinc Plated (1,848 components).

- Webforge Handrails - Steel - by Components, Cored, Cored Removable, Gates, Inground, One Ball Staunchions, Platform, Side 90, Side Conveyor, Side Offset, Side & Welded (1,200 components).

- Webforge Handrails - Jumbo Steel - Various Arrangements & Stair Arrangments (100 components).

The Vendor prepopulated metadata model libraries are vital and a huge time-saving feature that also increases the quality of the designs and project data, providing your team with data-rich models upon which to base your designs. Having Vendor model libraries dramatically reduces design issues such as selecting a vendor component not available in the marketplace. Say, for example, one of your designers models a vendor component inaccurately, which could lead to design interface issues; having these model libraries eliminates these issues.

We see the Vendor model libraries' development as a never-ending task and are constantly adding more libraries to the system. These are the Vendor model libraries that we are currently developing and will be supplied to you in the form of regular system updates once checked and completed,

Concrete

- Reid - Lifting Systems - Face Lifters, Combination Anchors, Eye Anchors, Foot Anchors, Void Formers & Lifting Clutches (50% completed).

Electrical

- Werma - Signals (50% completed).

- Kounis - Cable Ladders - C Range Cable Ladders (90% completed).

Mechanical

- Bradken Liners - Liner Plates & Wear Bars (50% completed).

- Rud - Lifting Lugs - 0.5 tonne to 250 tonne (5% completed).

- Nobles - Chain Blocks, Travellers, Trolleys (5% completed).

11 x Standards libraries have been created consisting of 5,802 components which are supplied with the system.

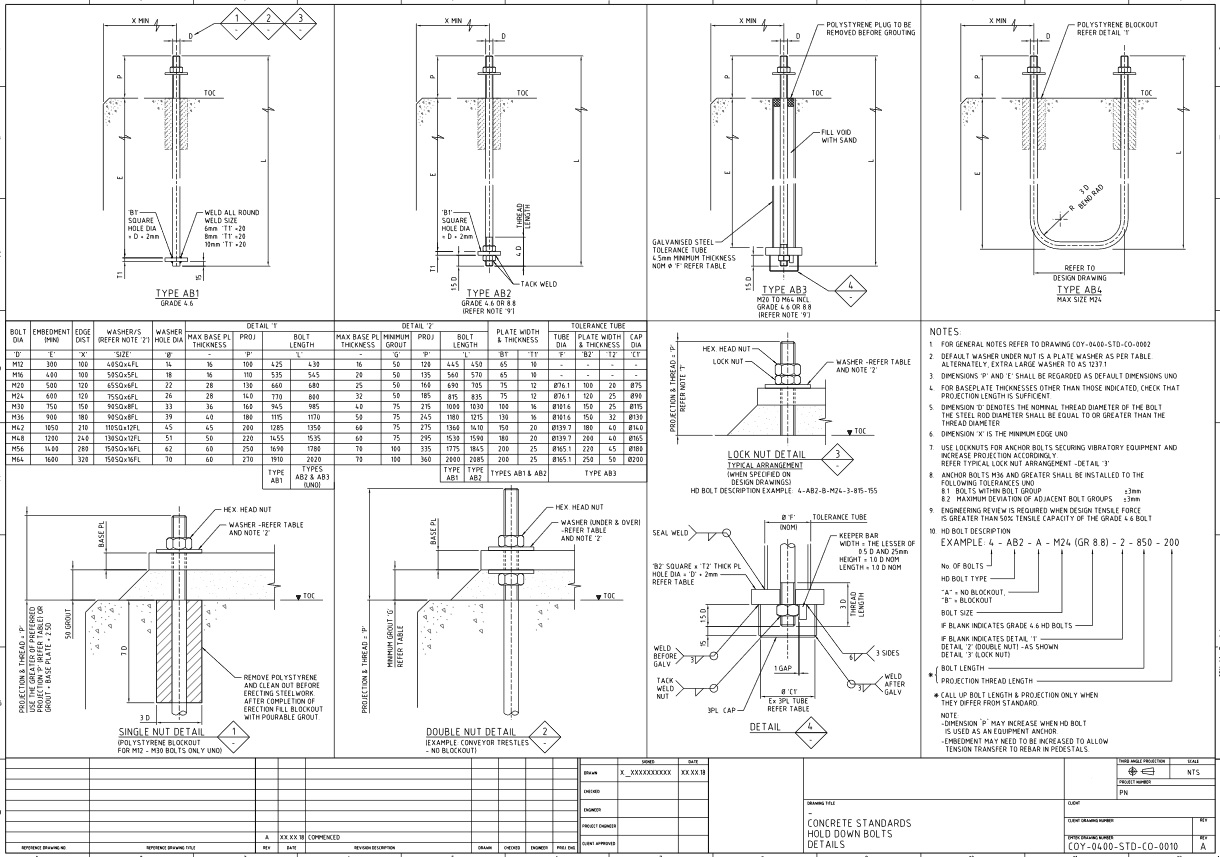

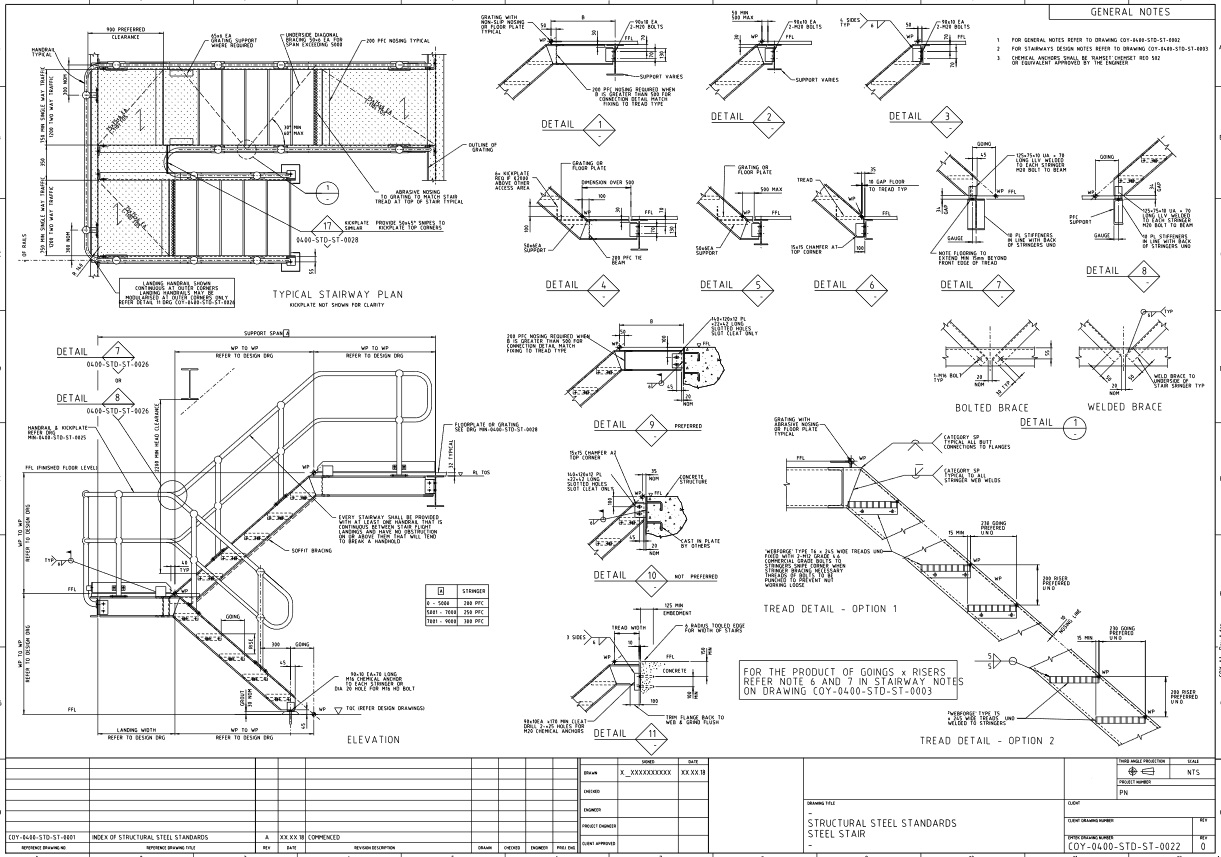

There are previously designed Standards Drawings for many well-developed components to cover Concrete, Structural, Electrical, Mechanical, and Piping disciplines. The purpose of the Standards Drawings is to minimize the amount of detailed design work required to develop the design by identifying the components that are standard in the industry. The Standards Drawings are usually in tabulated format and have many details on the one Standard Drawing which will cover many variations of the subject components.

An example of this is the Standard Drawing for Concrete Hold Down Bolts, where eight different types of Hold Down Bolts can be in 10 different sizes, which provides up to 80 different Hold Down Bolts detail design options.

Another example of this is the Standard Drawing for stairs, where the stairs can have 6 x different top connections, 5 x different bottom connections, 2 x different braces, bolted or welded stair treads, and can vary from 1 thru to 18 stair tread risers, this exponentially provides 2160 different detail design options for the stairs on the one drawing (more if you include Australian/Chinese Steel).

For prepopulated metadata Standards model library supplied by e3D is another component your Designers and Engineers do not have to spend hours, days, or weeks modeling; it only takes seconds to pick and place a model from the Standards libraries. The Standards model libraries allow your Designers and Engineers more time to focus on the actual design rather than modeling components from the Standards Drawings. Being prepopulated with the appropriate subject metadata means that it is instantly reportable as soon as the Designer places it in the model. The Standards Model libraries provide the cost estimators, schedulers, procurement, suppliers, transport, and installers with all the necessary and highly accurate data created from the single source of truth needed to perform these project activities.

We see the prepopulated metadata Standards model libraries' development as a never-ending task and are constantly adding more libraries to the system.

- Hold Down Anchor Bolts - Includes bends, plates & block outs to client standards.

Mechanical

- Sole Plates - To suit CBC or SKF brearing housings to client standards.

- Sole Plate Packer Plates - In singles and packs to client standards.

- Bearing Housing Assemblies - Includes Bearings, Bearing parts, Sole Plate Packers & Sole Plates to client standards.

- Sheaves - Includes Sheaves & Wire Rope Keepers to client standards.

- Lifting Lugs - All types of Lifting Lugs included in client standards.

- Baseplates - To suit all columns sections to client standards.

- Baseplates with Columns - To suit client standards.

Structural

- Lifting Lugs - All types of Lifting Lugs included in client standards.

- Baseplates - To suit all columns sections to client standards.

- Baseplates with Columns - To suit client standards.

We see the standards model libraries' development as a never-ending task and are constantly adding more libraries to the system. These are the prepopulated metadata Standards model libraries that we are currently developing and will be supplied to you in the form of regular system updates once checked and completed,

Concrete

- Conveyor Trestle Footings - As per client Standards (5% completed).

Mechanical

- Idlers - As per client Standards (20% completed).

- Pulley's - As per client Standards (5% completed).

- Liners - As per client Standards (10% completed).

Structural

- Stairs - As per client Standards (25% completed).

- Pipe Supports - As per client Standards (20% completed).

- Conveyor Trusses - As per client Standards (20% completed).

- Conveyor Ground Modules - As per client Standards (20% completed).

- Bolted Connections - As per client Standards (25% completed).

AECOsim has the benefit of all disciplines working together in parallel and working in one 3D environment. Due to this, there are many tools and 1,000's of Vendor and Standards model library components. E3D recognizes that finding what you are looking for enables your Designers and Engineers to work more efficiently. Imagine having to search thru lists of 1,000’s of components to find the one you need.

To solve this problem, we have introduced a user interface that is logical and easy to use so you can very quickly find the particular tool or component you are trying to find. We call it CADnet. CADnet does not replace any of the tools or library access from AECOsim but rather duplicates and organizes them into an easy to access interface (CADnet provides an optional toolset for your Designers).

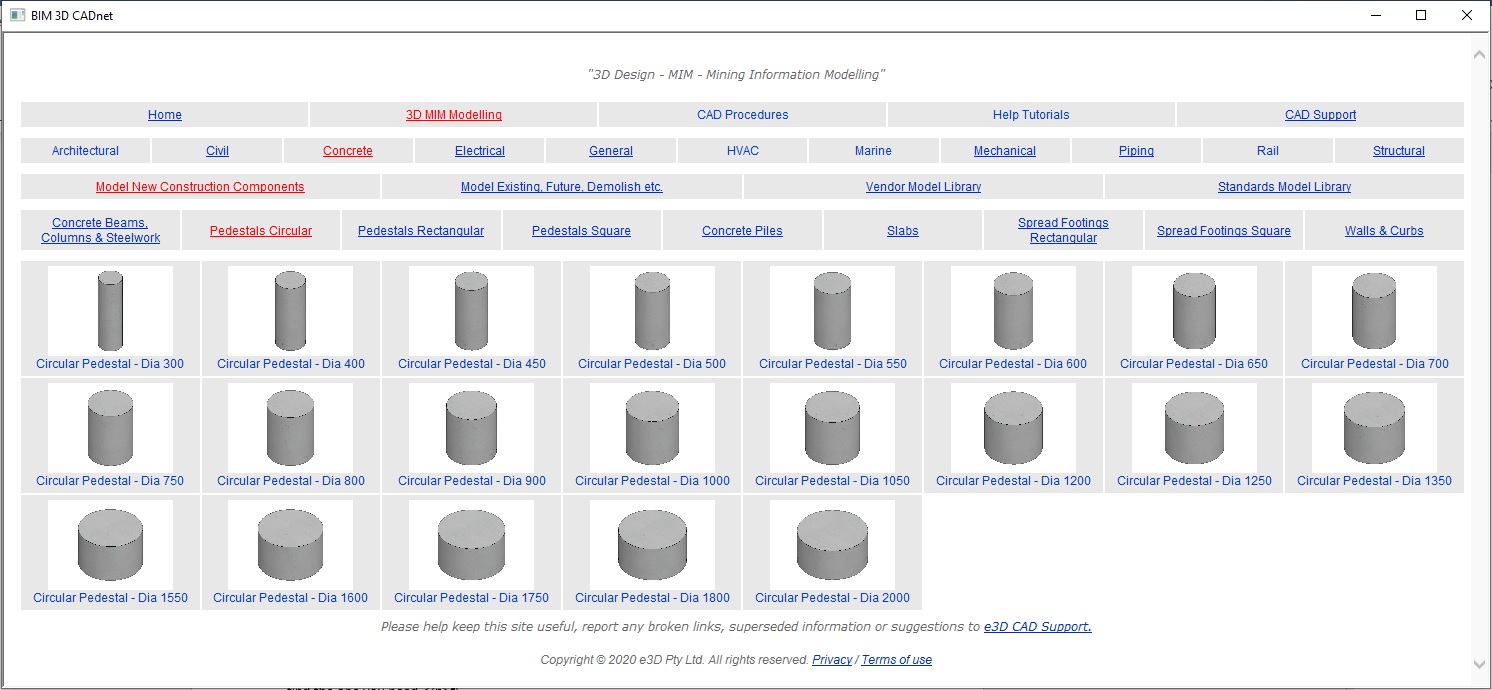

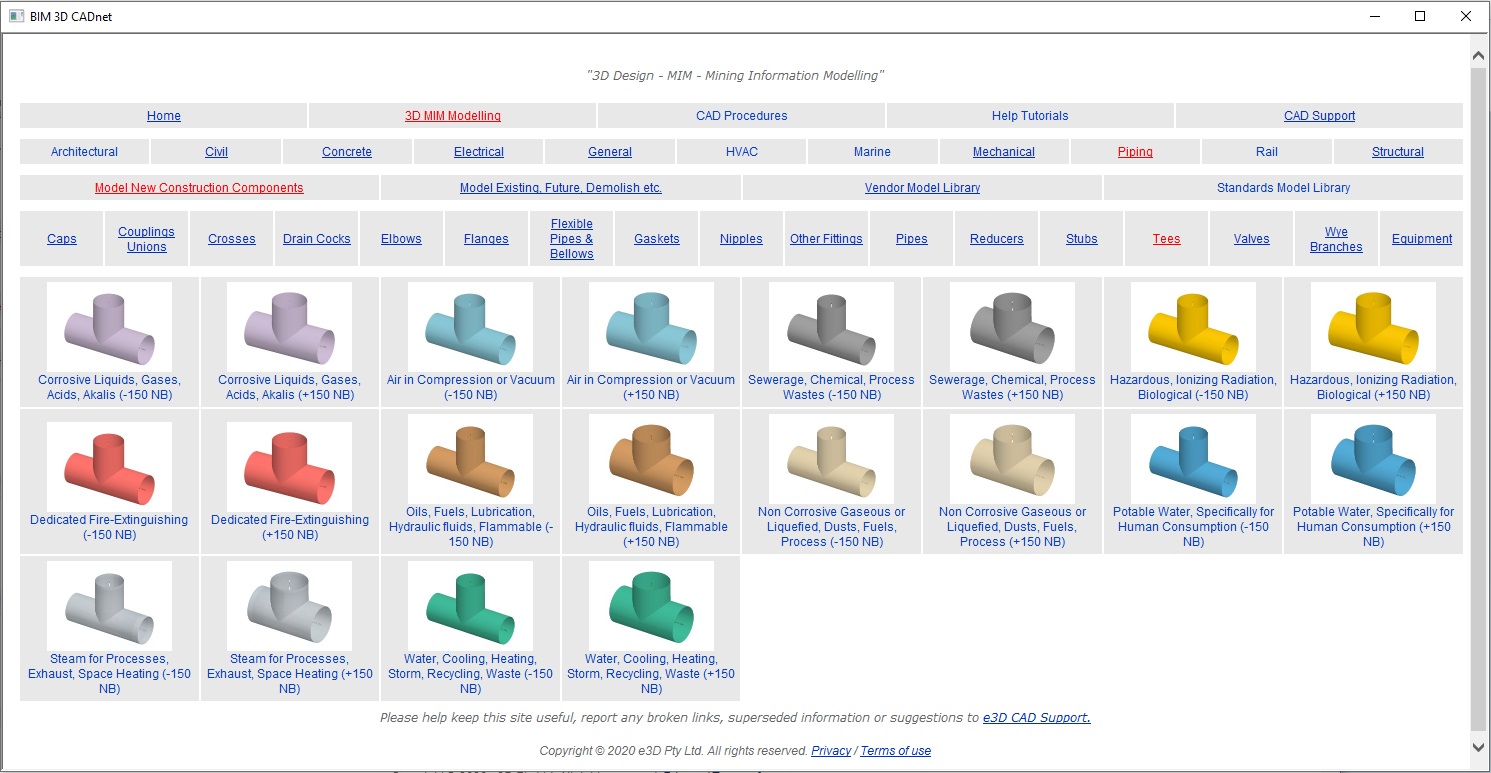

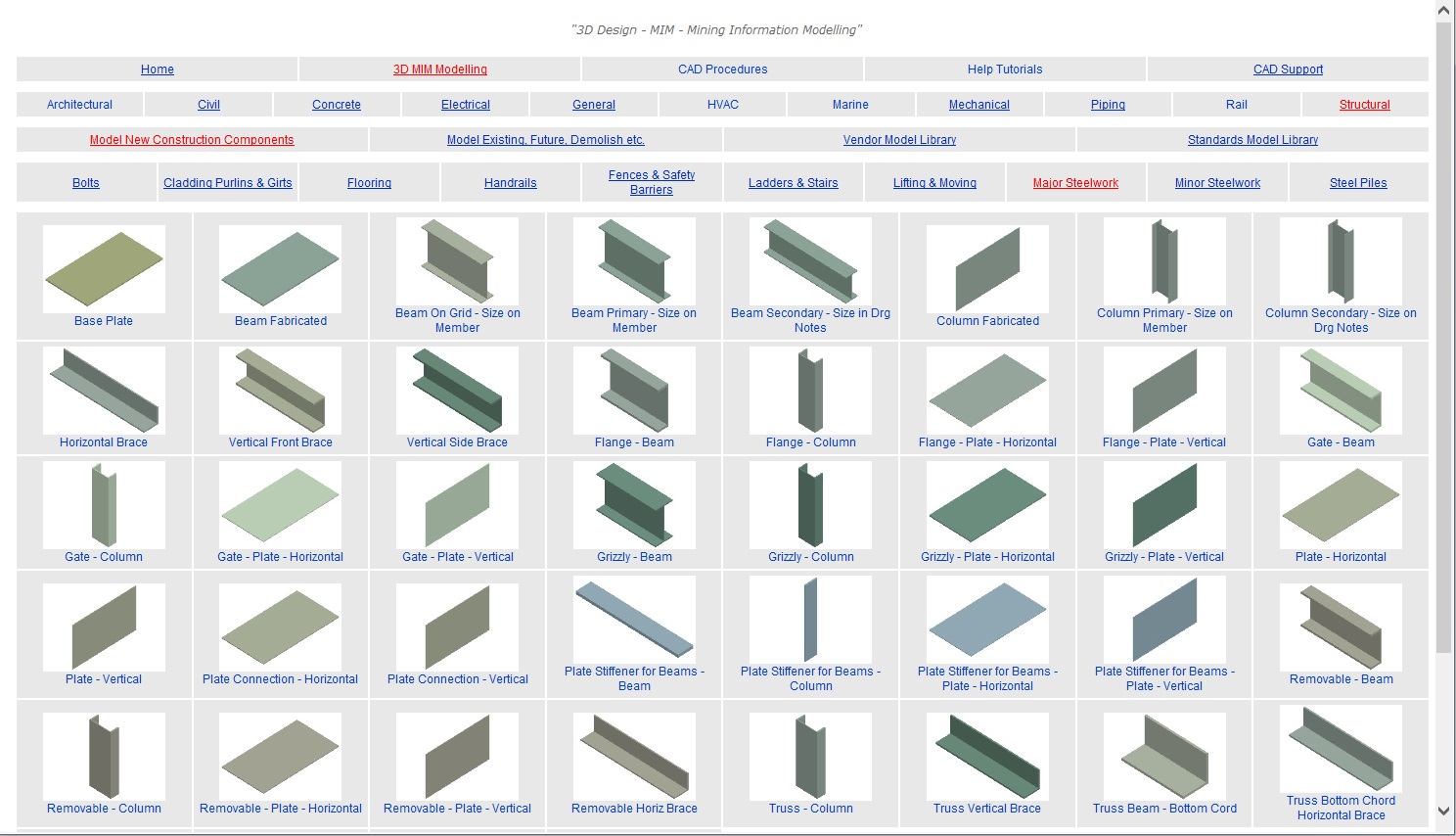

It is effortless to use; find what you are looking for, pick and place the item into your design model (so easy your CFO could do modeling). Here are some examples of the available tools.

Pick and place a Concrete circualar pedstal.

Pick and place a Pipe Tee.

Pick and place a major Strutural component.

Here are some examples of the available Vendor Model library components.

Pick and place an Electrical CCG Posifit Junction Box.

Pick and place a Mechanical CBC Brearing Housing.

Here are some examples of the available Standards Model library components.

Pick and place a standard Concrete Hold Down Anchor Bolt.

Pick and place a standard Structural Base Plate.

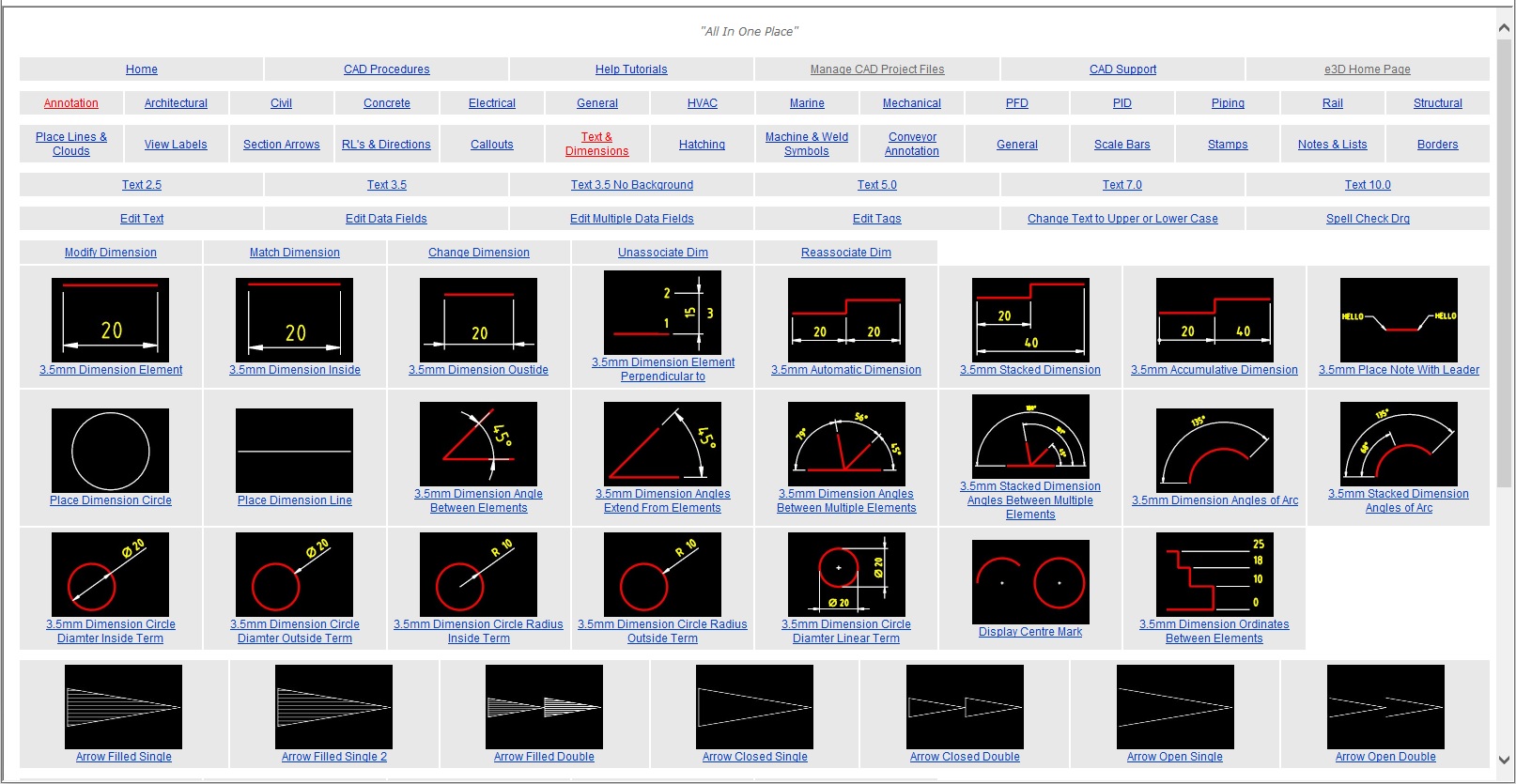

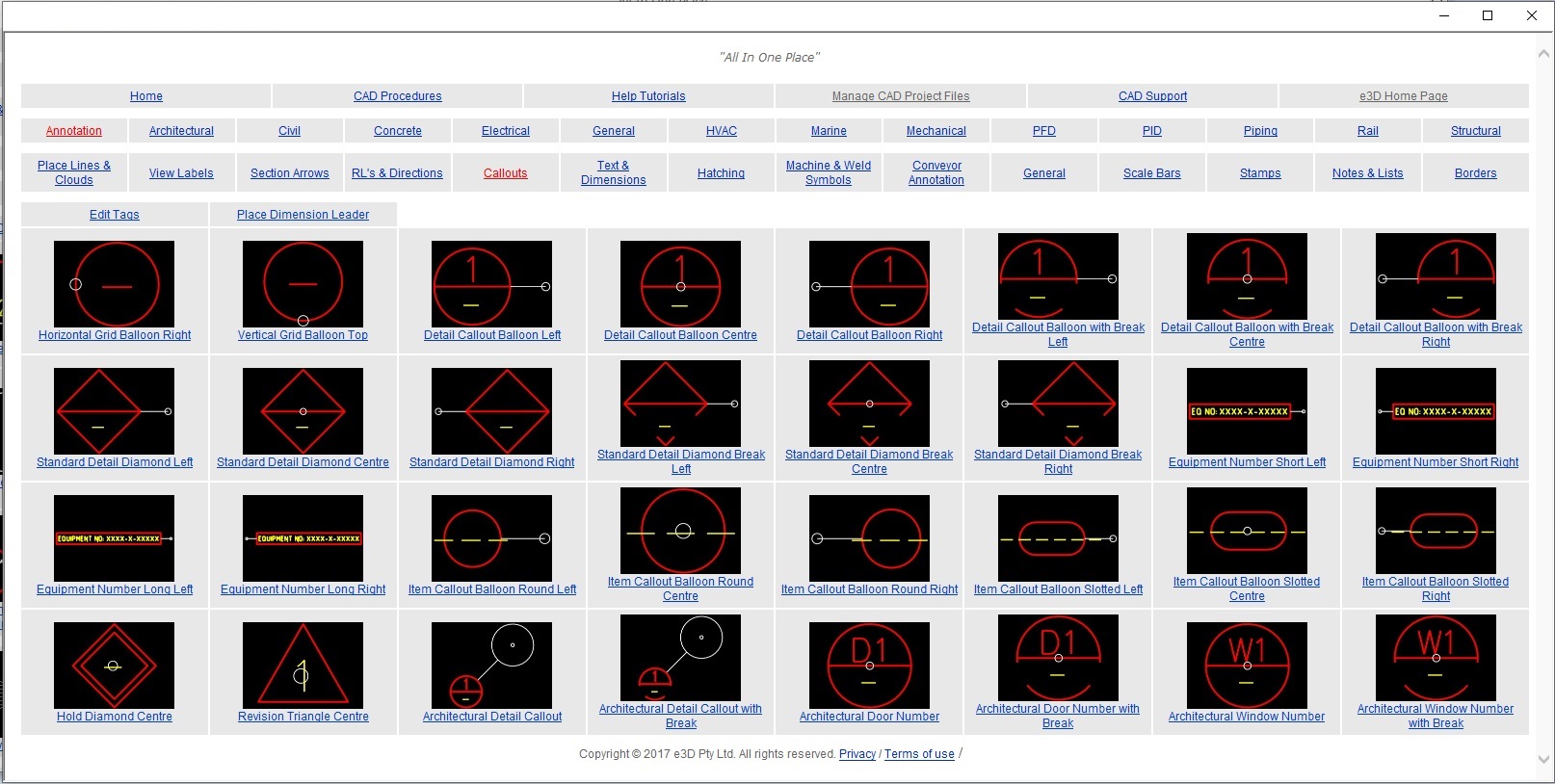

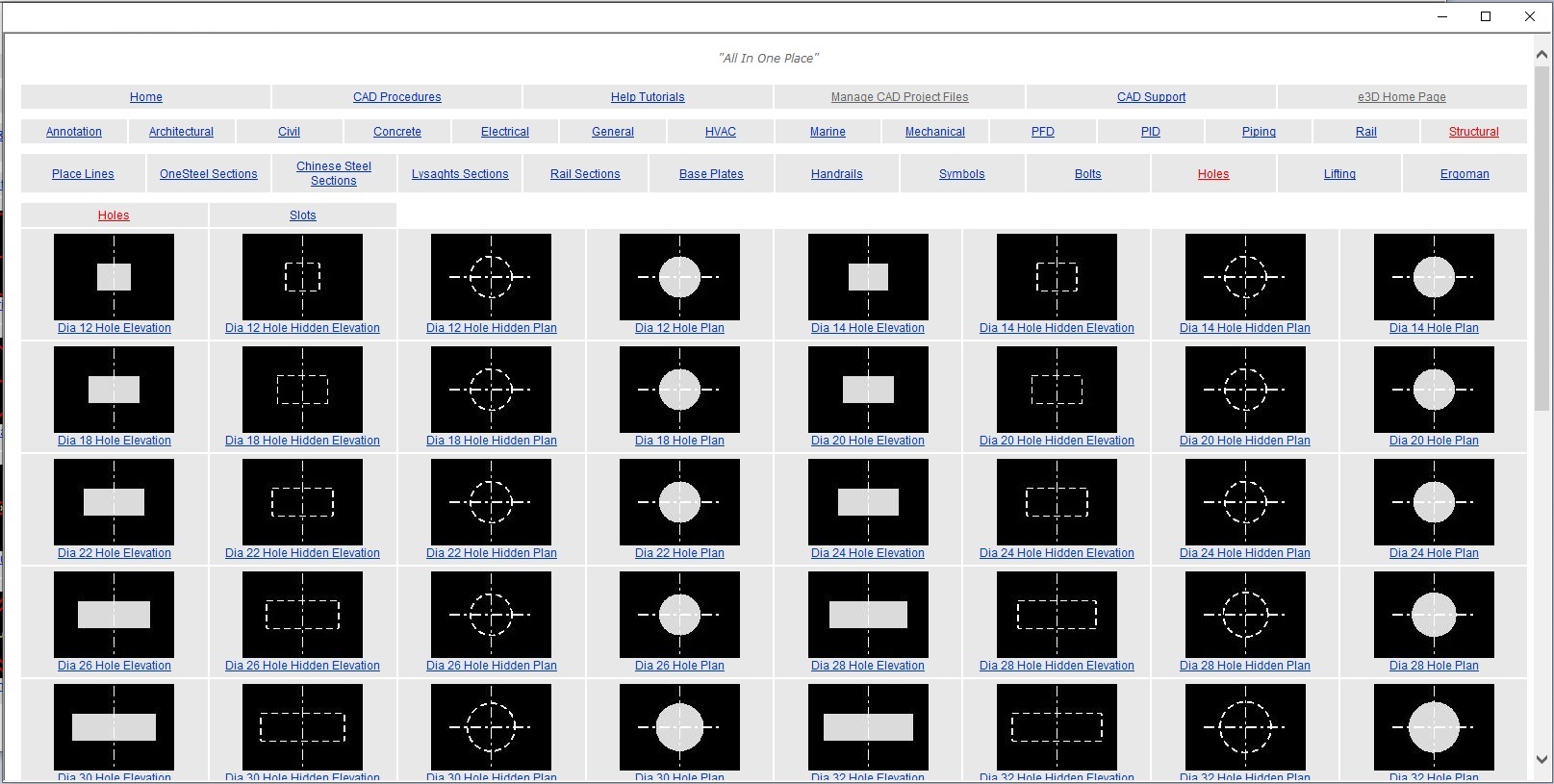

Like our 3D CADnet, the 2D CADnet user interface enables the Designer to find what they are looking for and pick and place the item directly into the 2D drawing. The 2D CAD systems come with many cells for the creation and annotation of the 2D drawings; we have found that by using the 2D CADnet we can save approximately 5 hours per drawing simply because we don’t have to sift thru long lists of tools and cell libraries.

Pick and place Text or a Dimension.

Pick and place an annotation Callout.

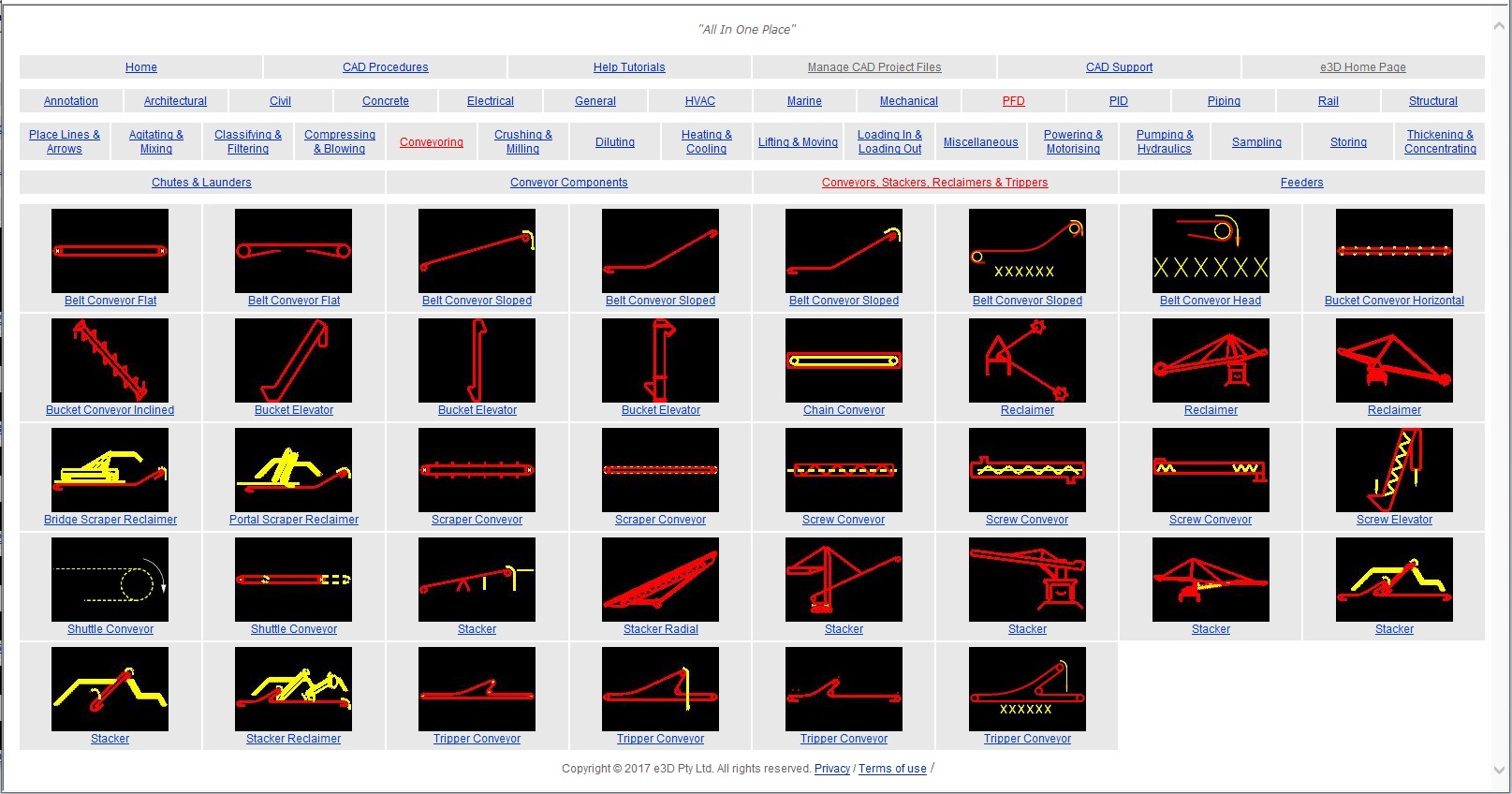

Pick and place a Process Flow Diagram cell.

Pick and place a Bolt Hole cell.

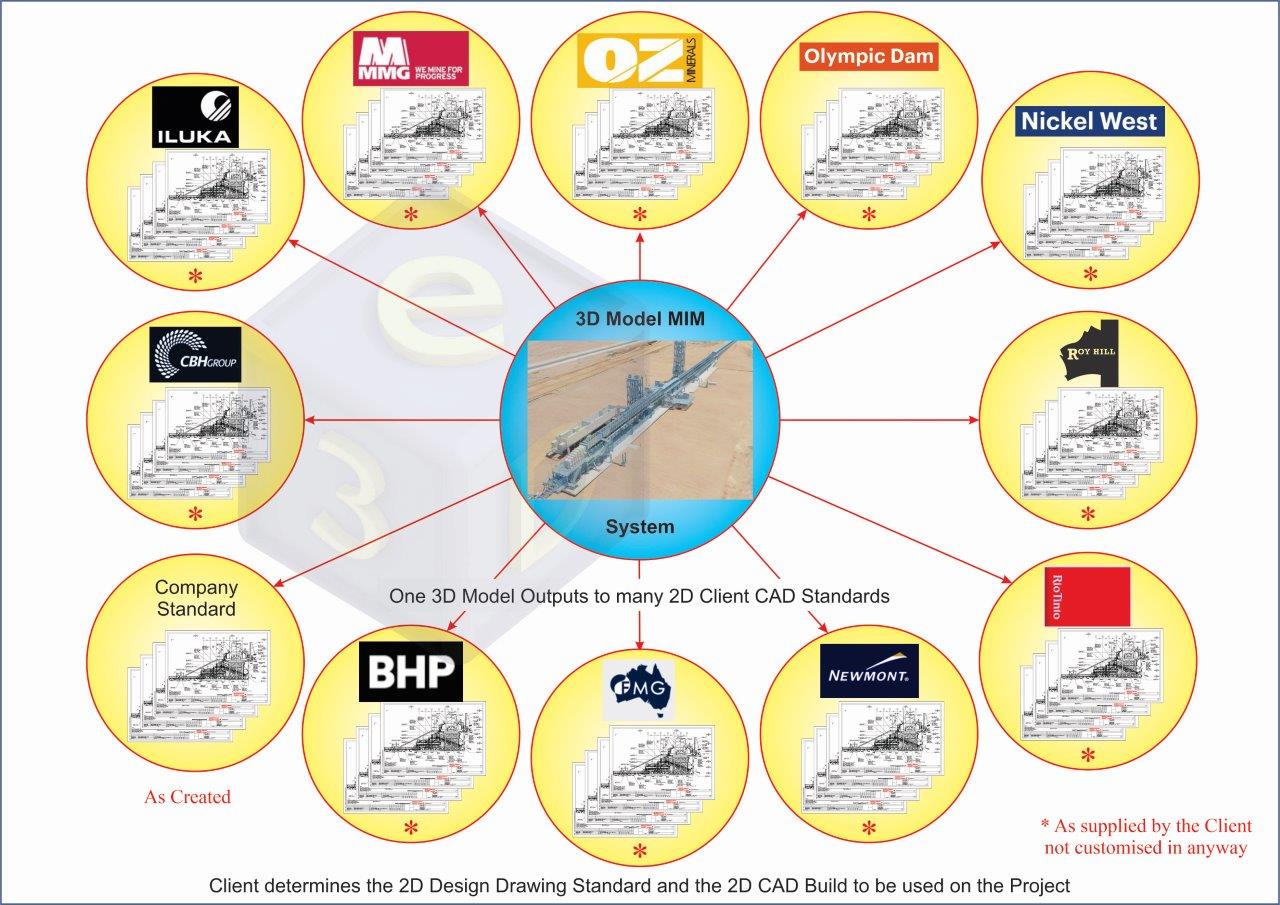

The importance and value of re-using previously designed project models (legacy project models) as a base for new projects can never be understated. E3D's MIM CAD Build is configured to have the one static 3D modeling environment that can use any 3D model and output it to many different client 2D CAD Standards.

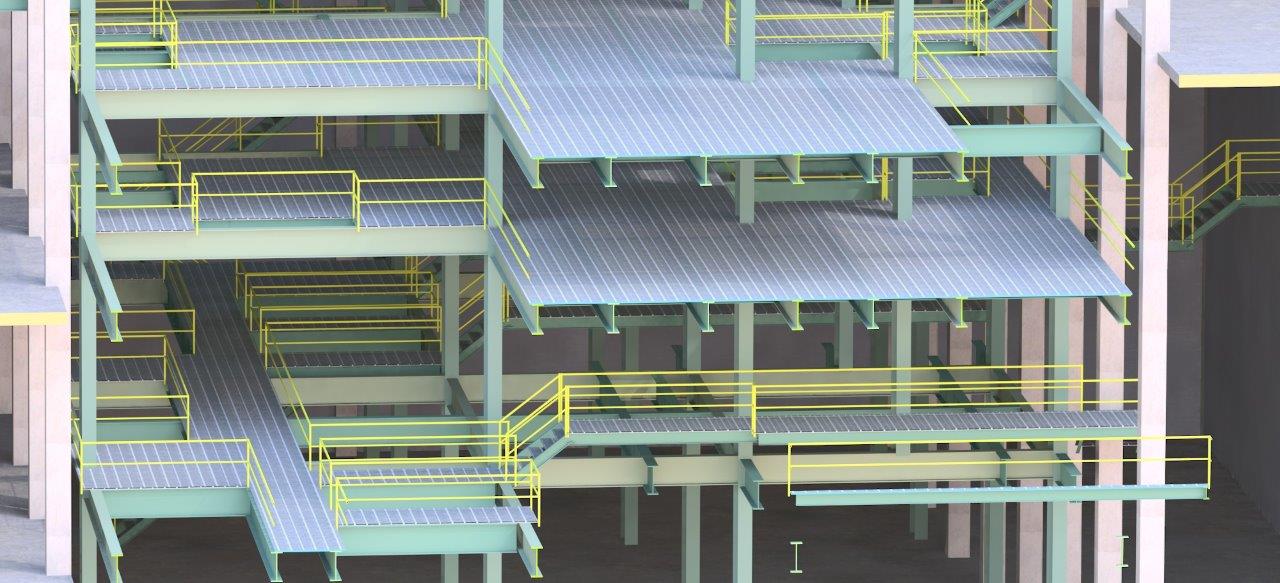

The materials for rendering have been configured to every component in the CAD Build. Concrete looks like concrete, and grating looks like grating; floor plate looks like floor plate; even the piping is to AS2700 colors to help identify contents. Nothing more is required other than using the render and animations tools within AECOsim; all the rendering material properties are in place.

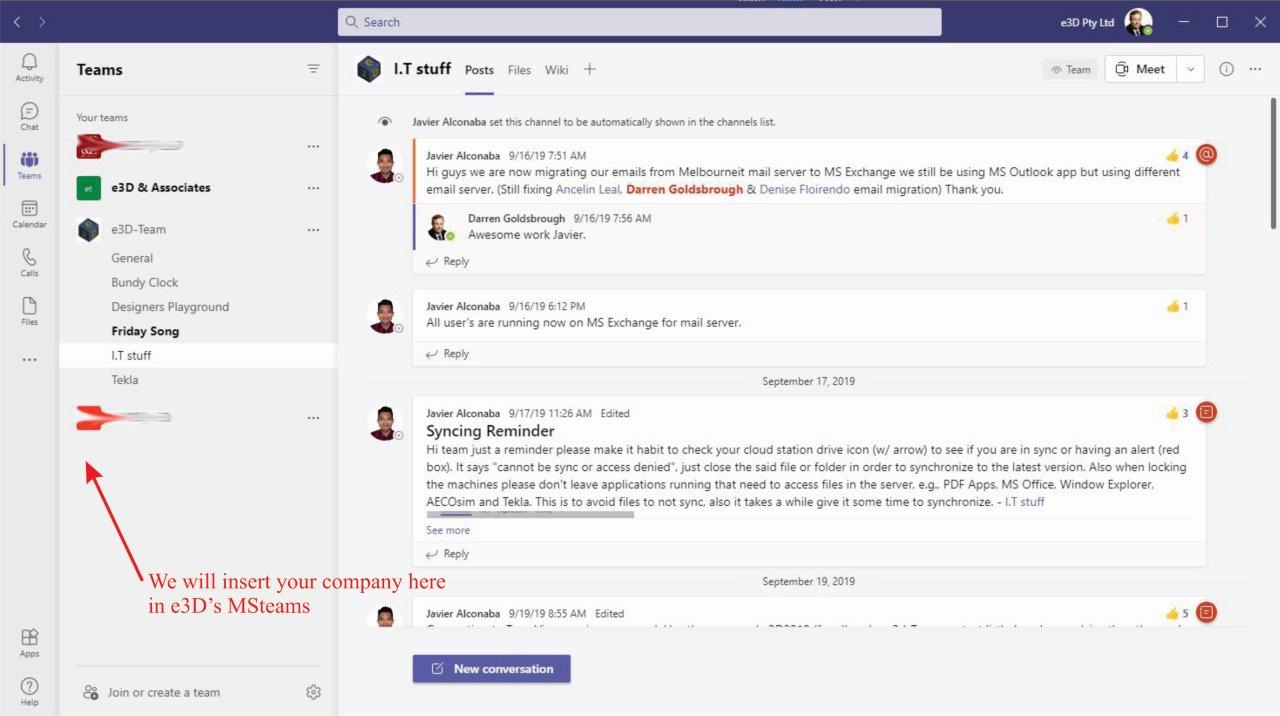

Once you are using the e3D MIM CAD Build, we will create a new account in our MSteams to display your company (only e3D will see this). Having an account will provide your Designers and Engineers direct access to e3D's CAD support team. Your Designers and Engineers will be able to chat, share screens where we can assist with any CAD support issues or if your users want to know how to do something.

We have produced many training videos that are available online. However, these were based on the V8i version of AECOsim rather than the latest Connect Openbuildings version of AECOsim. Both versions use the same tools, but the tools are displayed in different locations. e3D are in the process of updating the training videos to the Connect Openbuildings version of AECOsim. In the meantime, the current videos are still valid as training media. We believe the development of the Standards and Vendor libraries is a higher priority as learning to 3D model and create drawings is very easy to do. Should additional training be needed, then we can conduct group training sessions via MSTeams.

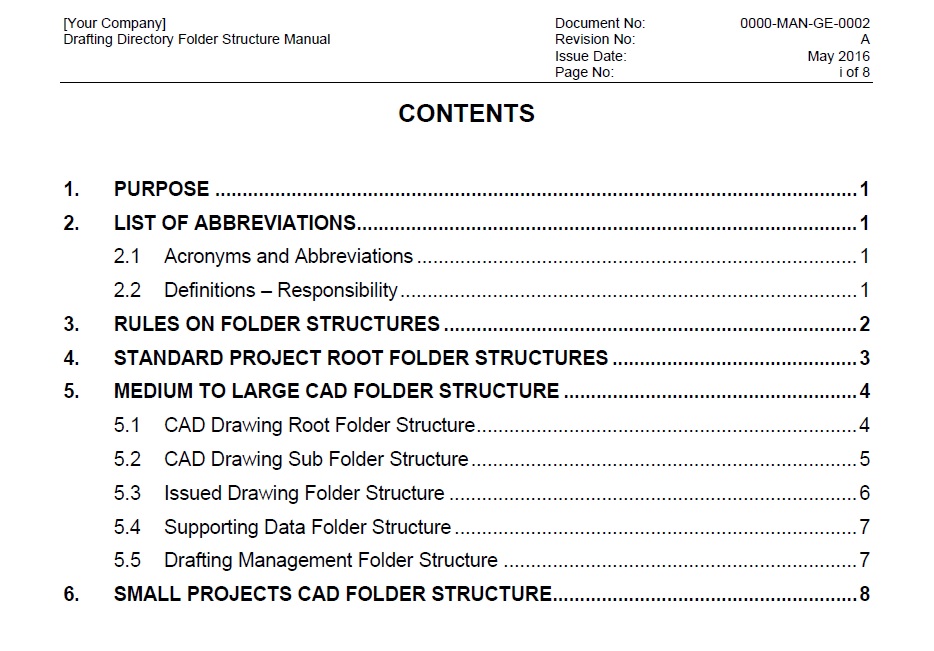

A complete set of procedures, guidelines, and definitions has been created for the MIM CAD system and are supplied with the system. These documents assist your Designers and Engineers as well as with your ISO9001 accreditation.